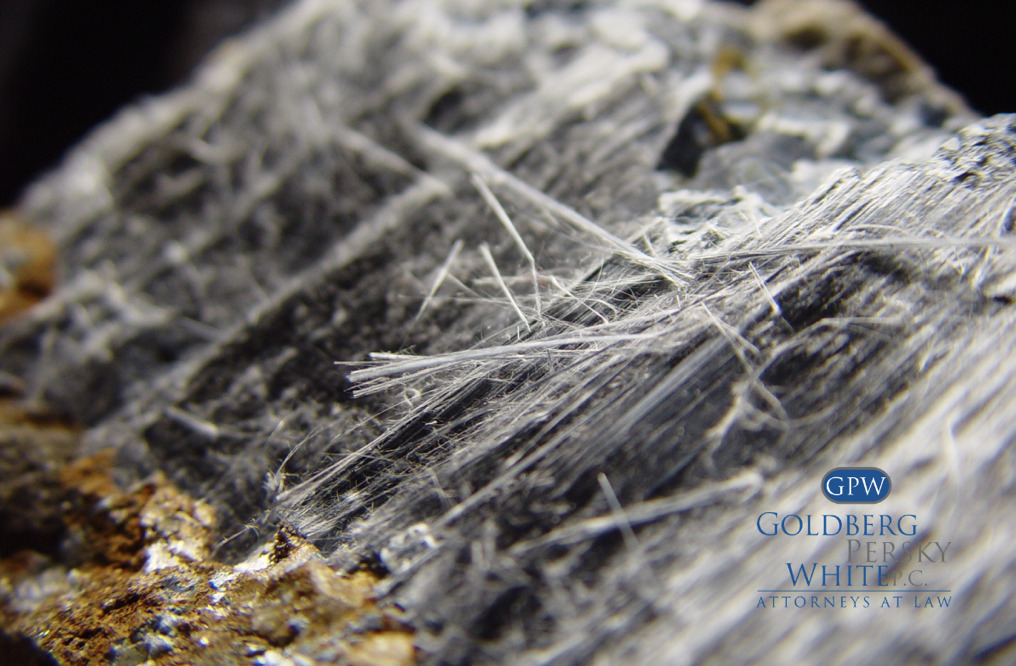

Asbestos Insulation

Before people knew about the dangers of asbestos, asbestos was known as this “miracle mineral,” used in a myriad of ways. From fire and sound proofing, to caulking and brake linings, the mineral’s heat resistant qualities, high tensile strength, and abundance made it a popular building material in the mid-20th century. Its numerous application methods meant asbestos exposure could affect any one from steel workers, chemical plant workers and other trades men who worked with the carcinogen, to bystanders and general homeowners who were exposed just because asbestos was used in the foundation of their home.

One of the most popular application methods for asbestos was for insulation because the fibers, even at their most delicate state, slowed down the transfer of heat. Naturally mined as a rock, asbestos is able to be pulled apart, revealing soft, yet strong fibers that are able to be mixed and transferred into other materials such as cement and spray- on coatings that were used in such insulation. In the early 1900s, asbestos shingles and pipe coverings were some of the most common asbestos insulation applications at that time. By the 1940s, the events from World War II resulted in a high demand for naval vessels and shipbuilding, and asbestos insulation became common throughout that industry. Asbestos use among the housing industry also increased in homes built in the 1950s and 1960s.

Types of Asbestos Insulation

While asbestos can be mixed into plaster and cement, and applied as electrical insulation for hot plate wirings, its thermal insulation applications can be grouped into four different categories.

Spray-On Insulation

Asbestos spray-on insulation was invented in the early 1920s, in an attempt to expedite insulation applications, and decrease the manual labor involved. Before the government began regulating the amount of asbestos used in the spray, the products at one point contained up to 85% asbestos. Spray-on insulation was used in a lot of commercial buildings and perhaps could most easily be spotted in areas like parking garages. Spray-on insulation was especially dangerous because the application itself allowed for the fibers to become airborne, which could then be easily inhaled. The spray-on method was also not the most structurally sound – the product could be easily damaged – sending asbestos fibers into the air.

Pipe Covering/Wrapping

To reduce heat loss, prevent freezing, control condensation, and save energy, asbestos was used as insulation for pipes, air ducts, and HVAC components. These coverings would be made out of asbestos-paper and wrapped around the pipe providing insulation and structural components. Asbestos paper, while overall strong can crumble overtime, especially along its outer edges. Once the paper begins to break down, there is nothing holding the dangerous asbestos fibers in place.

Block Insulation

As mentioned earlier, asbestos in its natural form is solid rock and it can be used in its natural form as block insulation. As the name suggests, the raw asbestos is cut into blocks and used to insulate large surface areas such as in the wall or siding of a building. Demolition workers and construction workers responsible for renovating or destroying these older buildings need to be aware that asbestos fibers can, and most likely, will be released when the asbestos insulation blocks are cut or disturbed in any way.

Loose Asbestos Insulation

Commonly used in attic insulation, loose asbestos was used for insulation partly because it could be maneuvered into small hollow spaces and crevices. This type of insulation was sometimes made entirely of raw asbestos fibers, and its fluffy light weight consistency meant that it could be disturbed easily.

Today, insulation materials such as fiberglass, foam board, polyurethane, etc., are used in place of asbestos, but that does not mean there is no longer a risk for exposure. Asbestos can still be found in many households today, and in cases where the asbestos-containing material is severely damaged, the fibers will become airborne and an asbestos contractor will be needed to professionally remove the carcinogen safely.

The slightest exposure can have long lasting effects on the body. The latency period between asbestos exposure and illness can be anywhere from 15 to 50 years and result in irreversible and often fatal conditions such as asbestosis, lung cancer, and mesothelioma. If you are suffering from an asbestos-related injury, contact the attorneys at Goldberg, Persky & White for a free case revi